What are the differences between type A B C & D fabric in FIBC industry?

When FIBCs/ jumbo bags are filled and discharged, the flowing of the finely powdered substances can cause a buildup of static electricity. Removing and or preventing an electrical charge is one of the most important things in the packaging of flammable and combustible materials OR in an environment where combustible dust is present. That’s why we have to know what materials/ substances you will use for jumbo bags to determine the right type of fabric to ensure safe handling of your product.

There are four specific types of bags A-B-C-D, each with unique features and safe uses. If you are working in jumbo industry or if you want to buy jumbo big bags for using, please find out the different types of FIBC fabric and how they should and should not be used.

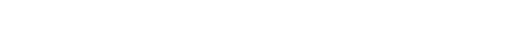

1/ Jumbo Bag – Type A

Type A FIBCs are made of plain-woven polypropylene PP and other non-conductive fabrics. Static electricity is generated as products move over or rub against the inside surface of the bulk bag when they are filled/emptied. There is no static protection provided by Type A FIBCs

Type A bulk bags can be used to safely transport non-flammable products. There should not be any flammable solvents or gases present around a Type A Jumbo Bag.

Type A jumbo bags are safe to transport non-flammable products or No flammable solvents or gases present around the bag.

Do not use type A bulk bags for:

– Transporting flammable products.

– When flammable solvents or gases are present around the bag.

– Should not be used where a flammable atmosphere with a minimum ignition energy ≤1,000mJ is present.

2/ Jumbo Bag – Type B

Type B are similar to Type A jumbo bags in that they are made of PP material or other non-conductive material and also do not have any mechanism for dissipating static electricity.

The difference between Type A & B : Type B are made from materials that have a low breakdown voltage to prevent an incident where highly energetic, and dangerous propagating brush discharges occur. Although Type B jumbo bags can prevent propagating brush discharges, they are not considered as anti-static bulk bags because they do not dispel an electrostatic charge.

You can use type B jumbo bags:

– To transport dry, flammable powders.

– No flammable solvents or gases present around the bulk bag.

– Intended to be used in environments with dust with ignition energies less than 3mJ.

Do not use type B bulk bags when flammable solvents or gases are present around the jumbo bag.

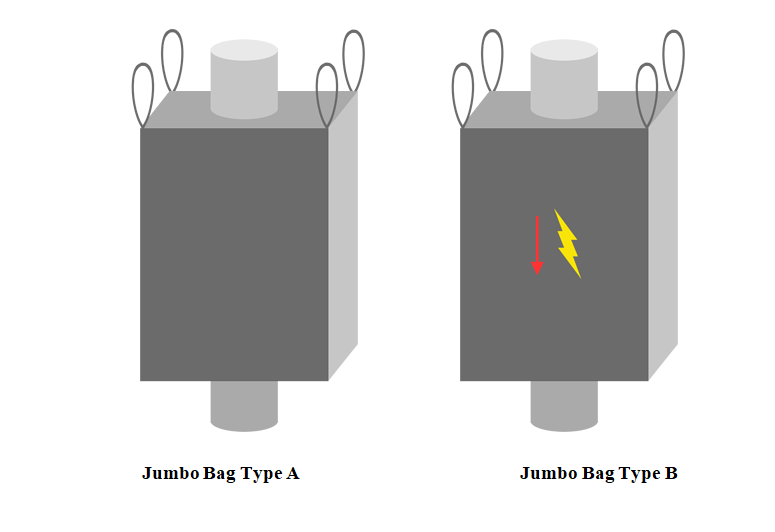

3/ Jumbo Bag – Type C

Jumbo Bag type C also known as conductive jumbo bag or ground-able jumbo bag, are made from non-conductive polypropylene fabrics interwoven with conducting threads traditionally sewn in a grid pattern. These conducting threads must be electrically interconnected as well as connected to a designated ground/earth during filling and discharging. This connection to the ground/earth during filling and discharging is imperative to the safe use of Type C bulk bags.

You can use Jumbo bag type C :

– To transport flammable powders.

– When flammable vapors, gases, or combustable dusts are present.

Do not use type C jumbo bags:

– When ground connection is not present or has become damaged.

– Resistance from any location FIBC to ground-able point.

4/ Jumbo Bag – Type D

Type D jumbo bags are made from antistatic and static dissipative fabrics designed to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges without the need for a connection from the jumbo bag to a designated ground/earth.

Type D jumbo bags are manufactured with fabric containing quasi-conductive yarns that safely dissipate static electricity into the atmosphere via safe, low-energy corona discharge. You can use Jumbo Bag type D to package combustible products safely and handle products in combustible and flammable environments.

Safe use for type D jumbo bags:

– To transport flammable powders.

– When flammable vapors, gases, or combustable dusts are present.

Do not use type D bulk bags: When surface of FIBC is contaminated or coated with conductive material such as grease or other flammable and or combustible materials.

About price, the cost of type D is the most expensive.

At Tu Phuong Jumbo bag Manufacturing, Jumbo bag type A is our strength. We are planning to produce other types of Jumbo bag in the future.

Please do not hesitate to contact us at info@tuphuongjumbobag.com.vn if you have any question or inquiries. We are happy to support you at any time!

-

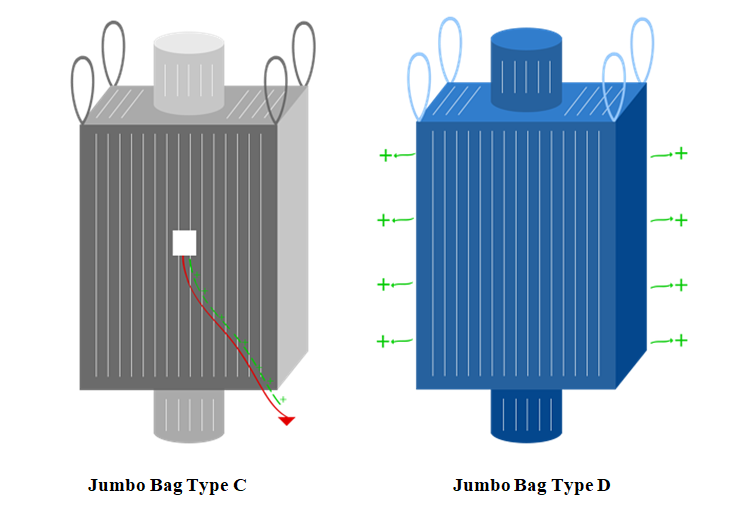

HACCP Certificate for Jumbo Bag FIBC Food Grade Packaging

HACCP Certificate for Jumbo Bag FIBC Food Grade Packaging

HACCP (Hazard Analysis Critical Control Point) is one of the most prestigious certifications in the food business all over the world. It is a method that gets approved internationally whenever it comes to recognizing and controlling the issues related to food safety. HACCP is also a management system in which food safety is addressed through … Continue reading HACCP Certificate for Jumbo Bag FIBC Food Grade Packaging

-

PP Jumbo bags with baffle

PP Jumbo bags with baffle

What is jumbo bag with baffle? This kind of FIBC Jumbo bags is manufactured with polypropylene baffles sewn across the four corners to increase their filling capacity to nearly 30% compared to standard FIBCs. So what is the differences between jumbo bag with or without baffle? With the Standard FIBC jumbo bag (or jumbo bag … Continue reading PP Jumbo bags with baffle

-

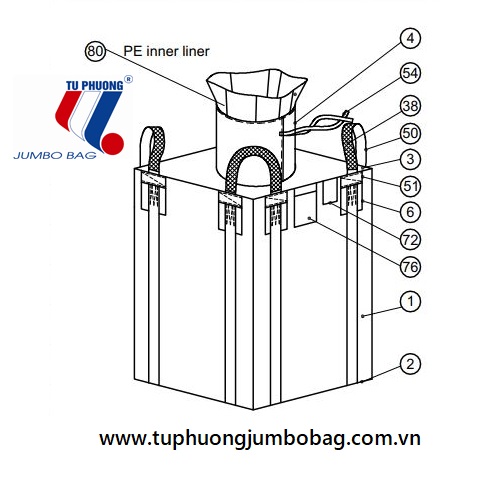

Jumbo Bag with PE inner liner

Jumbo Bag with PE inner liner

tJumbo Bag is widely used in packaging industry because of it’s advantages. To adapt the requirements of many customers, Tu Phuong Jumbo Bag Manufacturing can produce Jumbo Bag with PE inner liner (form-fit or tubular form) with various sizes and thickness. Tubular PE inner liner: This inner liner can be sealed at bottom (used for … Continue reading Jumbo Bag with PE inner liner