Jumbo Bag (FIBC bulk bag) is used widely in all over the world because of its advantages. Each jumbo bag will have its own safety called SF and when using FIBC bulk bags, it is very important to use them per the instructions provided by both your supplier and the manufacturer.

It is also important that you do not fill bags over their safe working load and/or reuse bags that aren’t designed for more than one use/trip. Most bags are manufactured for a single use bag but some are specifically designed for multiple uses.

What types of bags are reusable? What are differences between a 5:1 Jumbo bag and a 6:1 jumbo bag? What type of bag is right for your application? Lets find out all information in this article below:

What is a 5:1 Jumbo Bag?

Most woven polypropylene bulk bags (FIBC bag, Jumbo Bag, Sling Bag, Container bag, etc.) are manufactured for one use/one trip. These Jumbo bags are rated at a 5:1 safety factor ratio (SF) which means that they have the ability to be forced five times the amount of their safe work load (SWL). For example, Jumbo bag SWL 1000 kg, SF 5:1 mean that this bag can be forced 5000kg. However, you are not allowed to load more than 1000kg because it is unsafe and dangerous.

What is a 6:1 Jumbo Bag?

Some jumbo bags/ PP Big Bag are specifically manufactured for multiple uses. These jumbo bag has 6:1 safety factor ratio (SF 6:1), which means they have the ability to be forced six times their rated safe working load. Same as 5:1 SF bags, it is not recommended that you fill 6:1 SF bag over its SWL as doing so can result in an unsafe working environment.

Just because the bag is rated for multiple uses doesn’t mean you can use it over and over again without adhering to specific safe use guidelines. Multiple use/trip bags should be used in a closed loop system. After every use, each bag should be cleaned, reconditioned, and qualified for reuse. The bag should also be used for storing/ transporting the same product in the same application every time.

At Tu Phuong Jumbo Bag Manufacturing, we have the testing equipment to test this SF 5:1 or SF 6:1 to make sure all our products are good and safe to use.

To safely reuse bags, Tu Phuong Jumbo Bag Manufacturing suggests these guidelines should be followed:

1/ Cleaning

Remove all foreign matter from the bags interior.

Ensure statically held dust is less than four ounces total.

Replace liner if applicable.

2/ Reconditioning

Replace web ties.

Replace labels and tickets critical to safe woven polypropylene bulk bag use.

Replace cord-locks if necessary.

3/ Reasons for rejecting a bag/Not use again

Lift strap damage.

Contamination.

Damp, wet, mold.

Wood splinters.

Printing is smeared, faded or otherwise unreadable.

4/ Tracking

The manufacturer should maintain a record of origin, product used in the bag and the quantity of uses or turns.

5/ Testing

Bags should be randomly selected for top lift testing. The frequency and quantity shall be determined by the manufacturer and/or user based on their specific situation.

Which is right for your product and application?

5:1 SF jumbo bags are great for almost every product and application. Although using a bag multiple times has the potential to make your operation more environmentally friendly and cost effective, properly cleaning, reconditioning, inspecting, tracking and testing bags can be a time consuming activity that may reduce or ultimately cancel out the benefits of multi-use bags. It entirely depends on your specific operation and the resources you have at your disposal. In most circumstances, 5:1 SF bulk bags are the best fit.

If you have any inquiry of Jumbo bag, please do not hesitate to contact us at info@tuphuongjumbobag.com.vn. Our sales team will advise and support you the best!

Hope to cooperate with you soon!

-

HACCP Certificate for Jumbo Bag FIBC Food Grade Packaging

HACCP Certificate for Jumbo Bag FIBC Food Grade Packaging

HACCP (Hazard Analysis Critical Control Point) is one of the most prestigious certifications in the food business all over the world. It is a method that gets approved internationally whenever it comes to recognizing and controlling the issues related to food safety. HACCP is also a management system in which food safety is addressed through … Continue reading HACCP Certificate for Jumbo Bag FIBC Food Grade Packaging

-

PP Jumbo bags with baffle

PP Jumbo bags with baffle

What is jumbo bag with baffle? This kind of FIBC Jumbo bags is manufactured with polypropylene baffles sewn across the four corners to increase their filling capacity to nearly 30% compared to standard FIBCs. So what is the differences between jumbo bag with or without baffle? With the Standard FIBC jumbo bag (or jumbo bag … Continue reading PP Jumbo bags with baffle

-

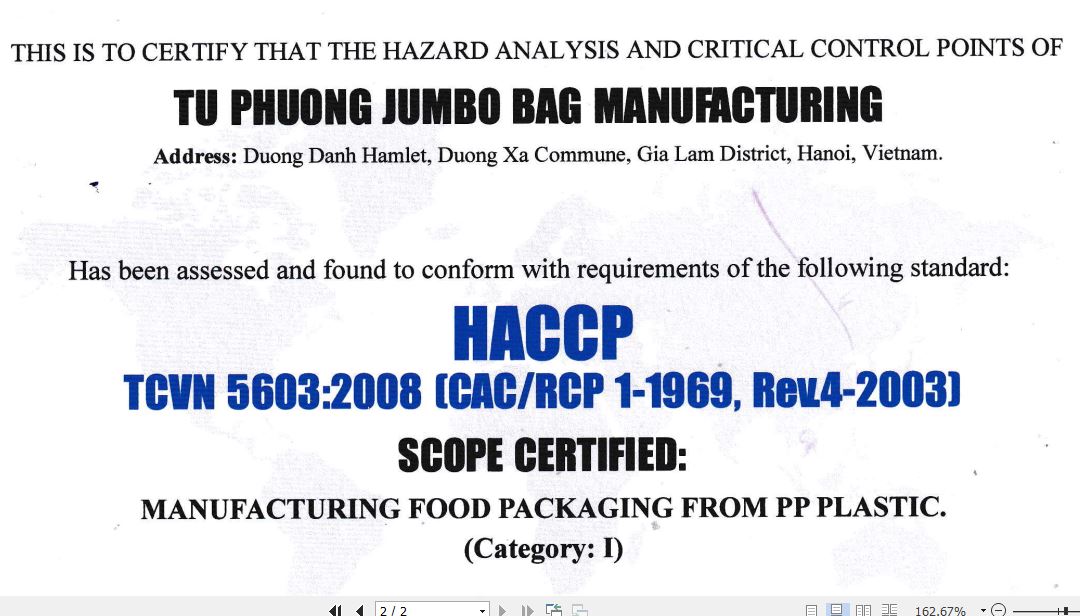

Jumbo Bag with PE inner liner

Jumbo Bag with PE inner liner

tJumbo Bag is widely used in packaging industry because of it’s advantages. To adapt the requirements of many customers, Tu Phuong Jumbo Bag Manufacturing can produce Jumbo Bag with PE inner liner (form-fit or tubular form) with various sizes and thickness. Tubular PE inner liner: This inner liner can be sealed at bottom (used for … Continue reading Jumbo Bag with PE inner liner