(23/4/2021)

To look up the last investment in a new BOPP film production line in Vietnam, one has to go back a long time. Based on this fact and due to the promising demand situation in Vietnam as well as in the Asia Pacific region, Vietnamese Plastic Chemicals Joint-stock Company (also known as Plaschem) realized the idea to be the first company to establish a brand-new, ultra-modern BOPP factory.

But a good idea is nothing without a good concept. Together with their partner Brückner Maschinenbau, Plaschem analyzed the situation very carefully. Markets, present and future applications, trends and volumes, converters’ and brand owners’ needs and the overall feasibility of an investment of this magnitude: all that had to be taken into consideration.

Finally, Brückner presented to Plaschem a tailor-made concept for a flexible 8.7m wide high-speed BOPP film production line of the latest generation. Moreover, Brückner provided an integrated “ready to go” solution with comprehensive peripheral and downstream equipment.

Mr. Bui To Minh, General Director of Plaschem, says: „When we searched for a partner for this project, we deliberately looked for more than just a machine supplier. As being a newcomer in the BOPP film industry, we decided for Brückner Maschinenbau as we are convinced to get the best state-of-the-art machine and the best overall support – starting from the first discussion over the full lifetime of the line. Furthermore, we decided to include also the peripheral and downstream equipment into the design, layout and scope of supply of Brückner. With this new BOPP line, we are in the position to produce highest quality film which shall boost our sales in Vietnam, where since many years no new line was installed.”

-

HACCP Certificate for Jumbo Bag FIBC Food Grade Packaging

HACCP Certificate for Jumbo Bag FIBC Food Grade Packaging

HACCP (Hazard Analysis Critical Control Point) is one of the most prestigious certifications in the food business all over the world. It is a method that gets approved internationally whenever it comes to recognizing and controlling the issues related to food safety. HACCP is also a management system in which food safety is addressed through … Continue reading HACCP Certificate for Jumbo Bag FIBC Food Grade Packaging

-

PP Jumbo bags with baffle

PP Jumbo bags with baffle

What is jumbo bag with baffle? This kind of FIBC Jumbo bags is manufactured with polypropylene baffles sewn across the four corners to increase their filling capacity to nearly 30% compared to standard FIBCs. So what is the differences between jumbo bag with or without baffle? With the Standard FIBC jumbo bag (or jumbo bag … Continue reading PP Jumbo bags with baffle

-

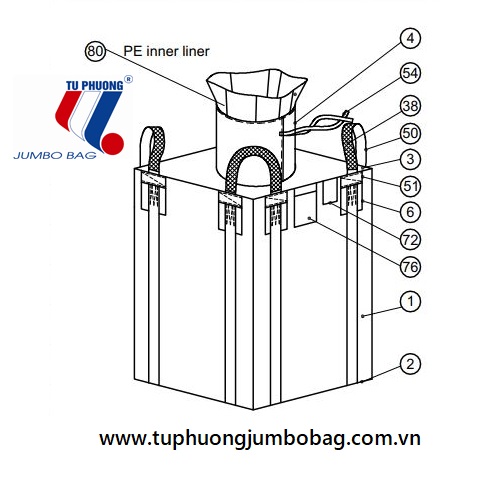

Jumbo Bag with PE inner liner

Jumbo Bag with PE inner liner

tJumbo Bag is widely used in packaging industry because of it’s advantages. To adapt the requirements of many customers, Tu Phuong Jumbo Bag Manufacturing can produce Jumbo Bag with PE inner liner (form-fit or tubular form) with various sizes and thickness. Tubular PE inner liner: This inner liner can be sealed at bottom (used for … Continue reading Jumbo Bag with PE inner liner